About Us

Supply Side

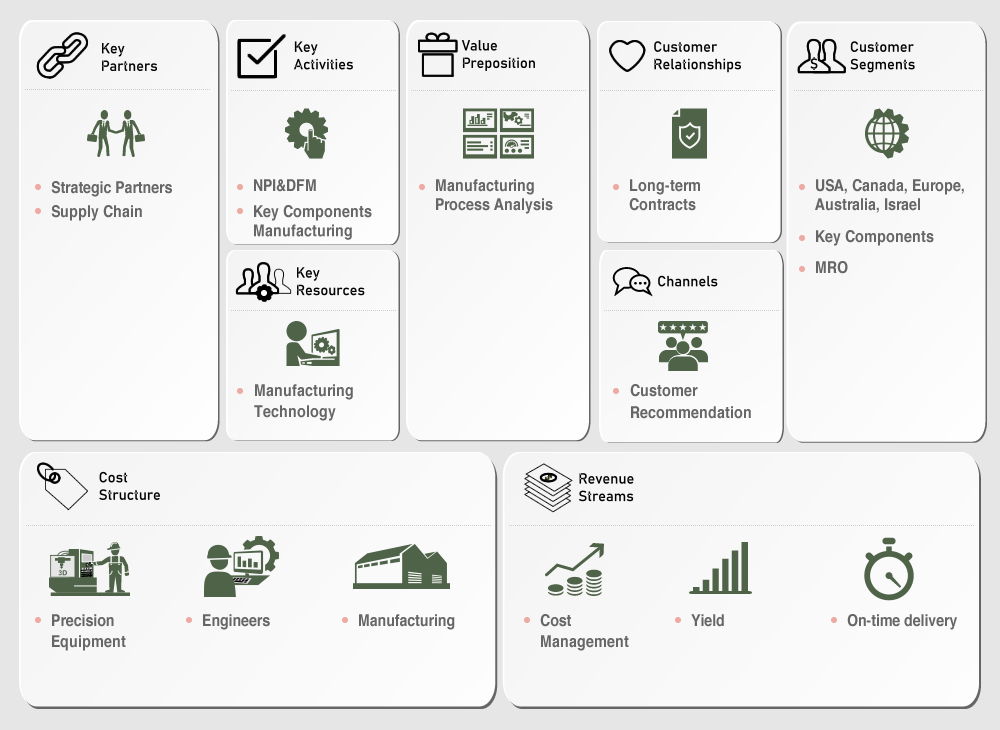

- Key Partnership

- More than 355 manufacturers and suppliers in Taipei, Taichung, and Tainan.

- Fast access to raw materials (except ITAR-controlled materials)

- Access to Japanese strategic partners and supplier resources

- Third-party certifying authority RoHS for raw materials and chemical processes

- Taipei, Taichung, Tainan, Yokohama, Kumamoto, and logistics networks to reach assembly plants and logistics centers around the world quickly.

- Third-party certifying authority RoHS and measurement inspection report, such as SGS.

- ISO certifying authority

- Key Activities

- Continuous optimization of process technology

- Efficient NPI & DFM to achieve cost target and yield improvement

- Annual information sharing and technical seminars from tooling and measurement equipment vendors.

- Supply chain partnership and quality yield review and improvement

- Supplier process discussions and technical guidance ...... from MasterSimon‘s engineering team

- Key Resources

- Simon Duh, founder of MasterSimon, has accumulated more than 35 years of experience in product manufacturing.

- Professional managers of process or equipment suppliers share their experience and apply the latest technology.

- Working team with more than 10 to 20 years of experience as R&D process engineers

- More than 20 years of experience in various process technology and cost management, with accumulated engineering quotation database in Taiwan.

- Efficient process stabilization CNC 5Axial & Mill Turn technology

Demand side

- Customer Relationships

- Accurate delivery time

- Yield improvement of parts and components

- Report on a thorough shipping inspection

- Analyze engineering drawings and read product specifications, carefully verify the process and cost relationship, and boldly tell customers what can be done or what can’t be done. What is the alternative if this does not work?

- Maintain originality of product design

- Strict product information management and sample confidentiality.

- Target Customer Segments

- Start-Up

- Camera Accessories

- Camera Accessories parts

- Industrial Products

- Aerospace parts

- MRO parts

- Satellite Parts

- Medical parts

- Customized parts

- Channels

- A good reputation comes from customer testimonials

- Professional manufacturer's website www.mastersimon.com

- Social network Linkedin

Value Side

- Value Propositions

- Precise process analysis and cost control by NPI & DFM

- On-time shipment of parts to designated assembly plants around the world

- Reasonable quotation and benevolence for customer's position

- Stable manufacturing process, improved yield, and reduced production cost

- Thorough inspection reports on shipments

- On-time delivery from small parts to large parts.

Financial side

- Cost Structure

- The cost of raw materials will increase in the near future due to the pandemic in 2020.

- We need to train our engineers in advance by reaching out to the university-related departments.

- We have to invest in the purchase of CNC process equipment, DMG MORI MAZAK FANUC.

- Annual budget to invest in CMM measurement equipment.

- Revenue Streams

- Our process experience and superior cost management, on-time delivery, help customers' products to be stable on the market, and the best profit equation.

- Stringent process yields can be improved, and factory production yields can be increased to sustain profitability.

Our business model solves your manufacturing challenges by using BMC strategic framework. If you want to learn more about how to stabilize manufacturing in Taiwan, please contact MasterSimon's engineering and sales teams now!