About Us

Why MasterSimon

- Manufacturing technology and process solutions.

The brain is good at image memory, the content into images to deepen the impression, to achieve the realm of unforgettable, in the key absorption of information, the brain will link images, images, and the brain will automatically edit the validity of memory, the key moment can immediately recall.

- The most efficient way to learn between design and manufacturing, Product Design, Mechanical Engineering, and Manufacturing Technology.

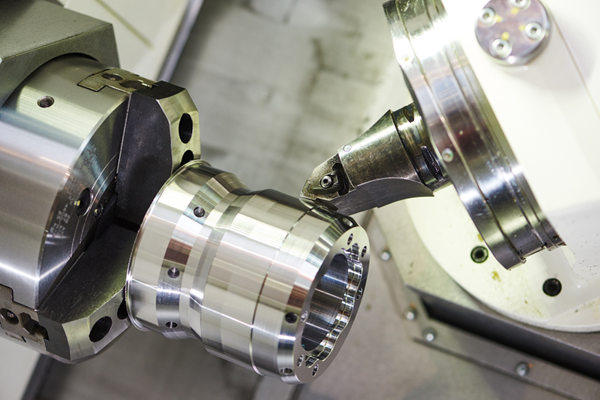

Based on engineering design drawings and specifications, including materials, geometric tolerances, process analysis, NPI, DFM, Project Management, Risk Managemen, Cost Management, and Stable Precision Parts Manufacturing.

- The engineering team of MasterSimon is responsible for reading engineering drawings and product or part specifications.

Through process analysis and SPC data, ensuring the yield of the first sample production and each risk management of the mass production in the factory, tracking the quality and engineering changes before and after the consistency.

Preciseness

Manufacturing combines a lot of process technology and process technology, yield, and cost control. Engineering Change is an important process control item in the face of market product competition. Obtain customer permission authorization in accordance with ECN, ECO, ECR, and ECA related procedures, whether new product or already mass production product optimization, facing internal process development improvement or mass production adjustments.

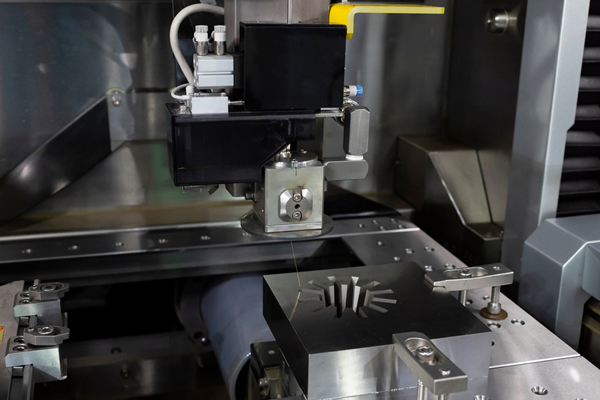

Flexibility

We have stringent engineering and quality procedures for manufacturing needs. We respond flexibly to changes in the market in response to immediate needs and business opportunities.

Faith

NPI Accurate Process Analysis and Design Change Recommendation, DFM creates maximum benefits for product development and component manufacturing. By utilizing DFM principles for product development and manufacturing to achieve maximum benefits.