Why MasterSimon? 8 Reasons to Trust Us as Your Business Partner – Your Partner in Advanced Manufacturing

MasterSimon – Your Partner in Advanced Manufacturing

In the realm of precision engineering and advanced manufacturing, MasterSimon stands as a beacon of innovation, quality, and efficiency. Our approach isn’t just about manufacturing components; it’s about creating comprehensive solutions tailored to the unique needs of our clients. Here's why MasterSimon is the choice of industry leaders:

-

1. Options: A World of Possibilities

At MasterSimon, we offer First Article Inspection (FAI) for critical parts, showcasing our commitment to quality right from the start. Our capabilities extend far beyond the typical – think of us as architects of the manufacturing world, designing solutions that fit your exact requirements. Our Tainan and Taichung factories are not just production sites; they're hubs of excellence where quality control is not just a process, but a culture.

FAI First Article Inspection

- 1. In the process of first production, the person in charge of the production line, inspectors should go to the production site to supervise and check the actual producer according to the production process, according to the current valid production process documents to complete the first piece, and to supervise and check each production process, problems found in a timely manner to correct and solve.

- 2. The first production of regular production products and products produced by stopping and starting again must complete all production processes, and after the producer has passed the inspection and signed on the first piece card, then handed over to the inspector for first piece inspection. During the first piece inspection, the inspector should work with the person in charge of the production line to carry out the inspection according to the current valid drawings, lists, process documents and product requirements, and after passing the inspection, label the first piece of product and have it signed by the producer (or representative) and inspector on the first piece card. For the first piece of inspection due to larger changes to the product can be signed by the relevant personnel and inspection approval; first piece of inspection failed to immediately return, redo the first piece.

- 3. The first batch production of new products and the semi-finished and finished products generated after the change of materials and specifications need to be inspected and confirmed.

- 4. The first piece inspection should be done in time to make the first piece record and fill out the first piece confirmation.

- 5. When quality problems are found in the production of the first piece, they should be reflected and handled in time, and the unqualified items should be reconfirmed. Only when the first piece is inspected and qualified, and the result is recorded on the first piece card, and the quality is approved by the inspector, can the production be organized.

- 6. After the first part confirmation, the inspector can start the normal delivery inspection work.

Many special patented parts are available from EVT DVT PVT ..... Before preparing for mass production, both parties must establish a stable manufacturing process according to the engineering surface level specifications.

-

2. Alternatives: Tailored Options and Feasibility Insights

Why settle for less when you can have the best? We understand the pain points of increasing non-conformity rates and the absence of effective Return Merchandise Authorization (RMA) processes in the industry. MasterSimon emerges as a reliable alternative, bringing a legacy of strict quality management and seasoned experts to the forefront. -

3. Communication: Bridging Ideas and Reality

Innovation thrives on communication. We pride ourselves on a team that not only understands but anticipates client needs, transforming them into viable, market-leading products. Our journey with you goes from prototype to mass production, powered by a seamless flow of ideas, feedback, and solutions.

Black Team

According to the customer's project requirements, we set up a project team and project office in a strictly confidential manner until the task is completed, and we keep the product confidential.

Who MasterSimon elites from NPI/DFM/PM/PFMEA/QC/CAM/CNC Team

Why Quick turn manufacturing solutions

What Top Secret project

When Kick off project

Where Confidential Zone

How On Time -

4. Relationship: More than Just Business

At MasterSimon, relationships are the cornerstone of our business structure. We're more than a supplier; we're a partner. In the ever-changing landscape of global manufacturing, particularly amid the geopolitical shifts, we stand by our clients, offering unwavering support and solutions that align with their evolving needs.

Best partner

Provide customers with a complete supply chain in Taiwan. Demonstrated experience interacting and effectively communicating with cross- Process Technology teams. Manage and work to ensure on-time delivery to the customer Work closely with various functional heads to drive operations excellence and continuous improvement.5. Geopolitical Acumen: Navigating Complexities with Finesse

In today’s interconnected world, geopolitical dynamics play a crucial role. MasterSimon not only understands these complexities but also turns them into opportunities. Our strategic locations in Taiwan, away from high-risk areas, ensure continuity and security in our operations, making us a resilient partner in challenging times.

6. Commitment: The MasterSimon Promise

Our commitment goes beyond words. We’ve spent years refining our process technology and cost management strategies, ensuring that we offer not just competitive prices but unmatched value. Our goal is to reduce procurement costs for our clients by about 30%, a testament to our dedication to your success.

Quality Specification

ISO 9001, ISO 13485, AS9100, NADCAP, AMS, ASME, MIL-STD, MIL-SPEC, GD&T(Geometric Dimensioning and Tolerancing), CMF-SPEC

If you're having trouble with sample-to-volume quality or on-time delivery from Asian suppliers, you should contact MasterSimon's engineering and quality control teams now!

Get Instant Quote.

Quality Control Process

PFMEA: (Process (process/manufacturing) FMEA)

IQC→PQC→IPQC→FQC→OQC→Shipment inspection report.

We consistently complete batch inspections and reports, even if the order is needed a year later, we perform the same production history and qualified inspection report in our factory to ensure that each part or mold is shipped as scheduled.

If you are looking for a supplier to perform a rigorous quality process, get a qualified inspection report from FAI, and also process SPC data analysis. Inventory batch management and inventory safety stock management are two features of the ERP system. Please contact MasterSimon’s Manufacturing Engineering team directly. Get Instant Quote

The requests range from Critical Components to complete mechanical BOM management, including finishes and inspections for mass manufacturing.

Multiple technological areas are covered by the Prototyping and Engineering team's expertise. We will implement 5-axis CNC and Mill Turn machining processes to achieve effective customer deliveries.

Get instant Quote.

Quality Inspection

GD&T Geometric Dimensioning and Tolerancing CMM Contour Measurement Micro Hardness Tester Surface Roughness Tester Salt Spray Tester COC COA RoHS Restriction of Hazardous Substances SPC Statistical process control

7. Quick Turn Manufacturing Capability: Agility Meets Quality

Time is of the essence in the manufacturing world, and MasterSimon excels in quick turn manufacturing. Our ability to rapidly prototype and scale to mass production without compromising quality sets us apart. With us, you get speed, efficiency, and excellence – all wrapped in one.

MasterSimon of Rapid Prototyping

Appearance Models

The advanced manufacturing technology behind your products

Based on the 35 years of product development experience accumulated by the founder of MasterSimon since 1984, he has led a team of professionals to serve numerous start-ups and large corporations, enabling the entire supply chain from development to mass production to be safely produced and manufactured in Taiwan. The founder and a group of experienced engineers review and analyze the appearance models.

3D printing cannot replace a team of experienced engineers

From 2010 to 2020, every country is developing, producing, and manufacturing 3D printing products. Of course, for non-precision size or special material verification, 3D printing is indeed a rapid prototyping option, but in terms of color, material, touch, and actual mass production weight, 3D printing cannot replace the review and analysis of appearance models by a team of experienced engineers with more than 35 years of experience.

From idea, design, and sketching...to mass production to bring the end customer's product to market successfully

Our team has rich experience in assisting our clients' designers from creativity, design, sketching...to mass production, and working with brands' design centers and design companies to achieve good teamwork to make products come true. To build a good relationship, we need not only good teamwork but also more empathy and originality, for the sake of the end customer how to smoothly bring the product to market is the biggest motivation.

The appearance model must present the greatest value in industrial design

From geometry and engineering drawings, we care about R-angles, C-angles, corners, arcs, ridges, and whether a plane is flat or not? Surface Treatment and Cosmetics of materials, how to present different surface variations, and color variations, this is the appearance model that must present the greatest value in industrial design.

"Creativity and design are made more beautiful by breakthroughs in process technology.

Products become brand marks because of rigorous process technology,

and cost control to win consumers' favor."

-MasterSimon-

Functional ModelsConfidentiality

MasterSimon has maintained product confidentiality for more than 35 years before our products are ready for production. (Learn more: MasterSimon-SOLUTIONS)

MasterSimon OEM has developed a good habit of never disclosing end-user information and becoming a silent supplier. The highest level of professional ethics and confidentiality standards are established, maintained, and implemented within the factory and among our employees to maintain the security of our customers’ intellectual property. - We sign and honor a Non-Disclosure Agreement with customers.

- Secure Rights Management Services system management for RFQ files.

- Data access restrictions through job assignment from IT systems to ensure that only project team members are authorized to access the project data.

- Employees are trained in product confidentiality and are required to sign a legally-binding product information security agreement.

- Product confidentiality training provided by legal counsel is arranged for all new employees at planned intervals.

-

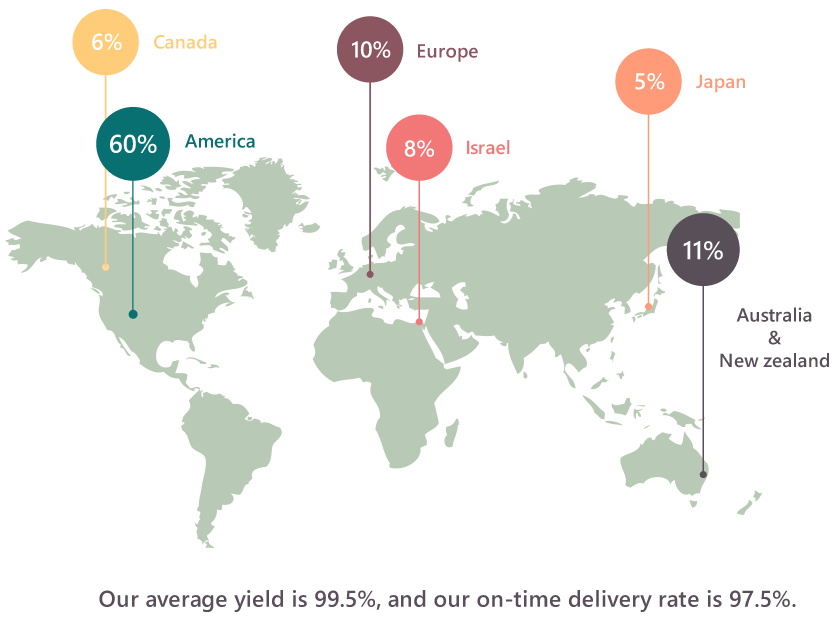

Mass production functional model, Product reliability, and On-time market launchThe strict process control and product confidentiality principle can be activated in Taiwan for the proprietary products of customers from Europe, America, Japan, Canada, Australia, and Israel. From BOM sheet to EVT prototyping and verification, NPI, DFM, cost analysis, yield analysis, and risk management are introduced in the process discussion of the functional model to ensure the assembly line goes online smoothly. Through a careful verification process that is close to the mass production functional model, product reliability and on-time market launch are the greatest values.

Perform critical product prototyping to mass production and turn start-ups from Start-Ups into core brand values

MasterSimon works hard to turn start-ups from Start-Ups into core brand values, and because MasterSimon exists to perform critical product prototyping to mass production, we strictly adhere to our OEM ethics of being a silent OEM and never revealing information about the end customer.

- Stringent physical and environmental access controls are in place to ensure that only the responsible project team has access to the project workplace.

8. Supplier Responsibility: Upholding the Highest Standards

As a responsible supplier, we adhere to stringent quality and delivery standards, aiming for a yield rate of 99.5% or higher and an on-time delivery rate of 98% or higher. We integrate superior surface treatments and quick turn machining into our supply chain, ensuring that every part we deliver meets not just the standards, but also your expectations.

Factory and Supply Chain Management (SCM)

The engineering team and manufacturing team in MasterSimon’s factory maintain the quality of the product specifications, detailed supplier planning management to ensure on-time delivery of each precision part during the NPI construction period with precise man-hour management, efficient management of production costs, accurate quality management, on-time delivery rate to meet customer needs Focus:

【NPI accurate manufacturing analysis and cost control】

【On-time delivery]

【Strict shipment inspection report Yield improvement of parts and components】,

【On-time delivery】【Strict delivery inspection report】

Supply components immediately, in a global mindset, enabling the team to maintain and develop a portfolio of reliable suppliers and metal processors to achieve outsourcing capabilities and capacity; address competing priorities and drive effective manufacturing/outsourcing deals with in-house production, applying supply chain knowledge to critical components (metals, plastics, modules, etc.) and contract manufacturing, each precision component we manufacture in Taiwan is delivered to the assembly plant on time and the location of your order requirements.

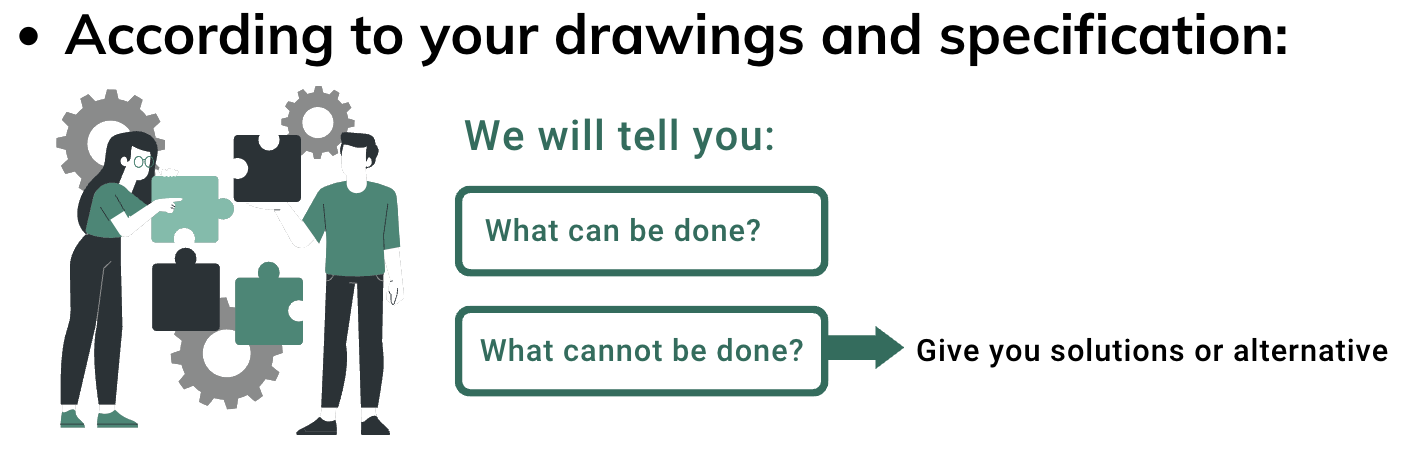

We provide process analysis, DFM, and quote in Taipei, Taichung, Tainan, Yokohama, and Kumamoto with more than 355 professional supply chain management, SQC SQA SQE. Because we are not Mr. No Problem!

We tell you what can be done according to the design drawings and specifications? What can't be done? What can't be done to solve ...... including cost issues? Material problems? Process problems? Quality problems? Through our 35+ years of process experience and defect rate improvement, we have been optimizing our manufacturing costs to clearly show you how to solve your manufacturing and shipping problems.

Supply Chain Management

- Global Logistics

- Outsourcing

- Strategic Sourcing

- CPFR、S&OP

- Risk Management

- Sustainability

Our factories have a wide range of processes and supplier management, with 355 suppliers in Taiwan and Japan performing full production histories and adhering to product specifications. Tell us what you need! We will plan a complete shipment plan to reduce inventory, and production costs, so that your capital is better spent on profitable business strategies. Please contact MasterSimon's Manufacturing Engineering team directly.

Get Instant Quote.

To complete the task safely in polar and extreme climates.

Please contact MasterSimon’s engineering team directly.